Our Extensive Awards List

A listing of Aristo-Cast’s achievements including casting awards, contest winners, castings of the year, best-in-class awards, and finalists.

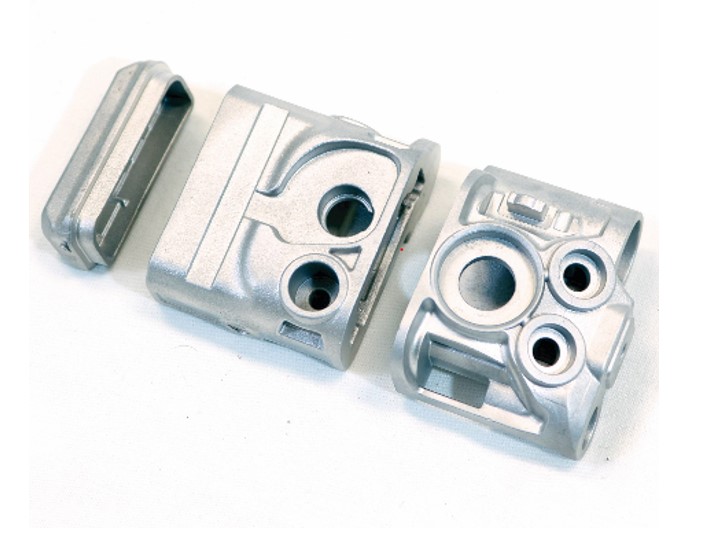

HONORABLE MENTION (May 2025):

ATLAS AFT / FRONT / MAIN HOUSING

ARISTO-CAST, INC. (ALMONT, MICHIGAN)

Material: AZ91E Magnesium

Process: Investment Casting

Weight: .06 lb.

Dimensions: 2.376 x 1.800 x 1.276 in.

Application: House Electrical and Optical Components for Laser Aiming Dev (Military/SWAT Forces/National Guard).

- Converted from a component machined from aluminum billet.

- Use of 3D Systems 2500IC printers allowed the foundry to create patterns for the investment casting process.

- Main purpose of the housings was to assemble and house the electrical and optical components required in a stable and inert environment – a high level of communication and exchange of ideas was therefore of utmost importance.

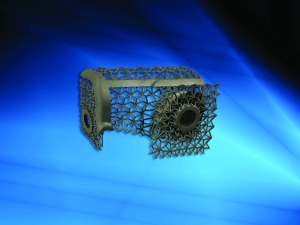

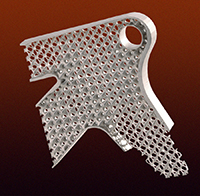

Best In Cast, 2024:

Mesh Trimmed Basket

Dimensions: 3.247 in. x 2.236 in. x 2.134 in.

Weight: 0.195 lbs.

Alloy: 17-4 PH stainless steel

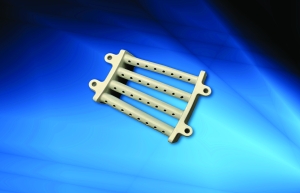

Casting Contest Finalist, Aerospace, 2024

Weight: 1.93 lbs.

Alloy: 17-4 PH stainless steel

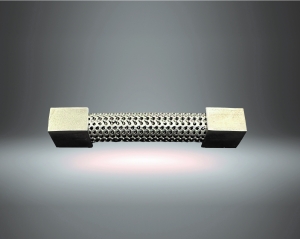

Casting Contest Winner, Automotive, 2024

Weight: 0.195 lbs.

Alloy: 17-4 PH stainless steel

Best in class, Medical, ICI 2023

Aristo-Cast Scores First Place Aerospace Award with PICS

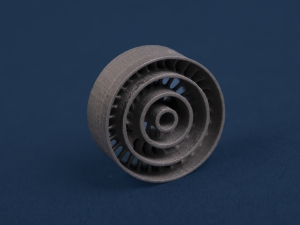

Fuel Injection Triple Swirler

Material: 17-4 PH Stainless Steel

Process: Printed Investment Casting Shell (P.I.C.S.)

Dimensions: 0.750” x 0.305”

Aristo-Cast takes 2022 Innovator of the year

Printed Investment Casting Shells (P.I.C.S.)

Presented by: Investment Casting Institute

Aristo-Cast Provides Bicycle Manufacturer With Flexible,

Light Weigh Alternative To Fabrication

Magnesium Racing Bike Node

Material: Magnesium

Process: 3D printed

Dimensions: 6.00 x 4.00 x.125″

Outstanding Achievement

Gyroid

Material: 356 Aluminum

Process: Printed investment castings shell.

Weight: 0.08 lbs. (35g)

Dimensions: 4 x 1.5 x 1.5 in. (10.16 x 3.81 x 3.81 cm)

Aristo-Cast takes 2020 Best Prototype or Innovation Award

Fuel Nozzle

Material: Stainless steel

Process: Printed investment shell

Weight: 115 grams

Dimensions: 2.5×1.5 x 1.5in.

Application: Aircraft jet engine and land-based turbines

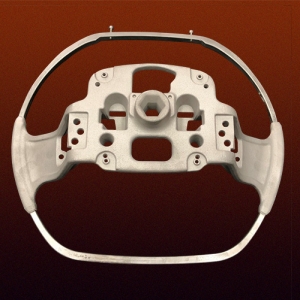

Aristo-Cast takes 2020 ICI Automotive award

Steering wheel

Size: 15.77 x 15.77 x 4.440 In.

Alloy: A357 Aluminum T6 Condition

Notes: Casting Conversion from die casting

Aristo-Cast is 2020 ICI Finalist

Mirror Bracket

Size: 12.00 x 4.00 x 1.25 In.

Alloy: A357 Aluminum T6 Condition

Notes: Casting conversion from die casting

Aristo-Cast takes 2020 Architectural Hardware award

Park Bench

Size: 59.00 x 41.50 x 30.00 In.

Alloy: A357 Aluminum T6 Condition

Notes: Casting conversion from fabrication/weldment

Aristo-Cast Takes 2019 Autodesk Design & Manufacturing Excellence Award

Volkswagen Group of America Project

Aristo-Cast Takes 2019 Automotive Casting Award

Generative Design Wheels

Size: 18″ diameter, 7.05″ deep

Alloy: A357 Aluminum

Notes: Traditional manufacturing collaboration with additive manufacturing creates one-of-a-kind wheel.

Aristo-Cast Takes 2019 Architectural Hardware Casting Award

Egg Vase-Light Accent

Size: 7 .00 x 14.50″ tall

Alloy: 300 Series Stainless Steel

Notes: Investment casting and additive manufacturing combine to create complex casting.

2018 Finalist

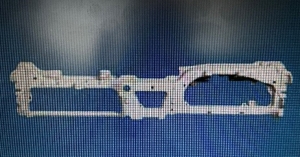

Instrument Panel

Size: 11.800 x 10.700 x 53.500”

Alloy: A356 T6

Notes: Investment casting of instrument panel serves as prototype for die casting proof of concept.

2018 Finalist

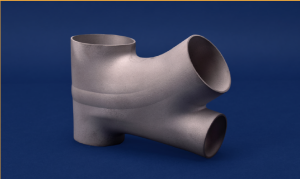

Induction Wear Tube

Size: 2.90 x 3.21 x 8.38”

Alloy: 17-4pH

Notes: Investment casting created from weldment conversion enhances design and functionality of part.

2018 Casting Contest Winners

Steering Wheel Armature

Size: 13.350″ x 12.150″ x 5.00″

Alloy: 304 SS and AZ91E Magnesium

Notes: Redesign of steering wheel simulates the die casting, produced in 5 days.

2017 Casting Contest Winners

Oil Pump

Size: 8 x 10 x 8 inches

Alloy: A356 Aluminum

Notes: Complex investment casting solves difficult customer specifications.

2017 TCT Awards

Magnesium Seat Frame

TCT Awards, Birmingham Town Hall, Birmingham, UK 27 September 2017

Following some strong competition and an intensive review by the TCT Expert Advisory board declared Aristo-Cast’s ‘Magnesium Seat Frame’ has been shortlisted for the Aerospace Application category for the TCT Awards 2017.

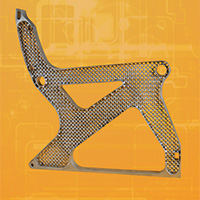

2017 AFS Casting Of The Year Winner

Aerospace Seatback Frame

- Material: Magnesium

- Process: Investment Casting

- Weight: 1.7 lb

- Dimensions: 17.4 x 17 x 0.8 inches

- Application: Lightweight seatback frame supporting passenger seats in aircraft.

2016 Casting Contest Winner

Hall of Honor Casting

- Size: 2.75 x 8.25″

- Alloy: Aluminum

- Notes: This fine art casting was created using a 3D scan of a foundryman.

2016 Casting Contest Finalist

Pilot Tube

- Size: 7.100 x 1.375″

- Alloy: Inconel 625

- Notes: Fabrication conversion improves design and reduces cost.

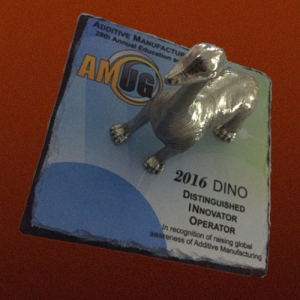

2016 Distinguished Innovator Operators Award (DINO)

Jack Ziemba, Aristo-Cast, Inc.

2015 Automotive Award

Cradle Casting

Size: 17” x 17” x 13” Alloy: Aluminum A356

Notes: Application of in-house rapid prototyping techniques affords opportunity to protect customer’s schedule on pre-production hardware when sand casting source failed to produce the parts.

2015 Fine Art Award

Spirit of Detroit

Size: 3.5” x 2.7” x 1.55” Alloy: Carbon Steel 4140

Notes: Using scanning and 3D wax printing technology, the statue was recreated from 26 feet to 2.5 inches and investment cast without losing any detail.

2015 Finalist

Specialized Robotic Arm

Size: 14.250” x 2.700” x 1.75” Alloy: Magnesium AZ91E Notes: Originally machined from solid aluminum, this magnesium investment casting saved valuable weight, cost and time

2015 Finalist

Terminal Connector

Size: 2.250” x 1.500” x 0.800” Alloy: Si Bronze Notes: This investment casting for the automotive industry has a wall thickness of just 0.5mm.

2013 Honorable Mention

Presented by: Investment Casting Institute

1932 Rolls Royce Ghost Windshield Bracket Assembly

2012 Industrial Casting Award

Aluminum casting measures 4.7” x 4.5”x 1.25”

The investment casting process not only produced a main valve body for a two-stage converter for LP-gas engines, but also the tooling needed to cast the complex component. The myriad of cast-in features eliminated extra machining, resulting in huge cost savings.

Aristo-Cast reverse engineered the part to create a solid model file of the tool design using 3D Systems Themo Jet machines to create wax patterns of the tool and all the core pins.

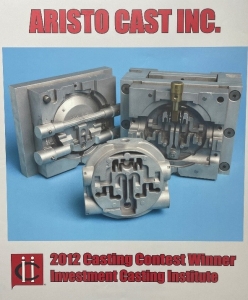

2012 Casting Contest Award

Presented by: Investment Casting Institute

For: Outstanding Leadership In Demonstrating The Benefits Of The Investment Casting Process.

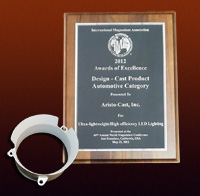

2012 Awards of Excellence

Presented by: International Magnesium Association

Design-Cast Product Automotive Category

Ultra-lightweight/High efficiency LED light

2012 Casting Contest Award

Presented by: American Foundry Society Inc.

Best in Class- Ultra-lightweight/High efficiency LED light

2010 Best-In-Class

Presented by: American Foundry Society Inc.

Laparoscopic Surgery Instrument

2007 Casting Contest Award

Presented by: Investment Casting Institute

For: Outstanding Leadership In Demonstrating The Benefits Of The Investment Casting Process.

2006 Casting Contest Award

Presented by: Investment Casting Institute

For Outstanding Leadership In Demonstrating The Benefits Of The Investment Casting Process.

2005 Best-In-Class Award – Magnesium

Presented by: American Foundry Society Inc.

Windshield Wiper

Motor Components

2004 Casting Contest Award

Presented by: Investment Casting Institute

For Outstanding Leadership In Demonstrating The Benefits Of The Investment Casting Process.

2004 Honorable Mention Award

Presented by: American Foundry Society Inc.

Swing Arm for Military Vehicle