P.I.C.S (Printed Investment Casting Shell) Process

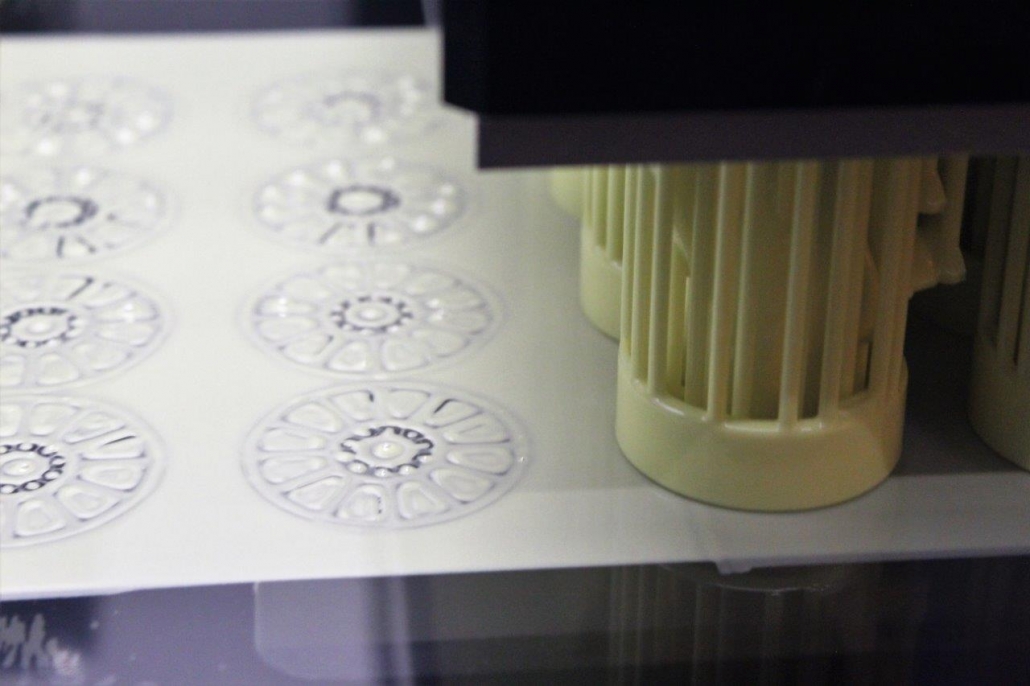

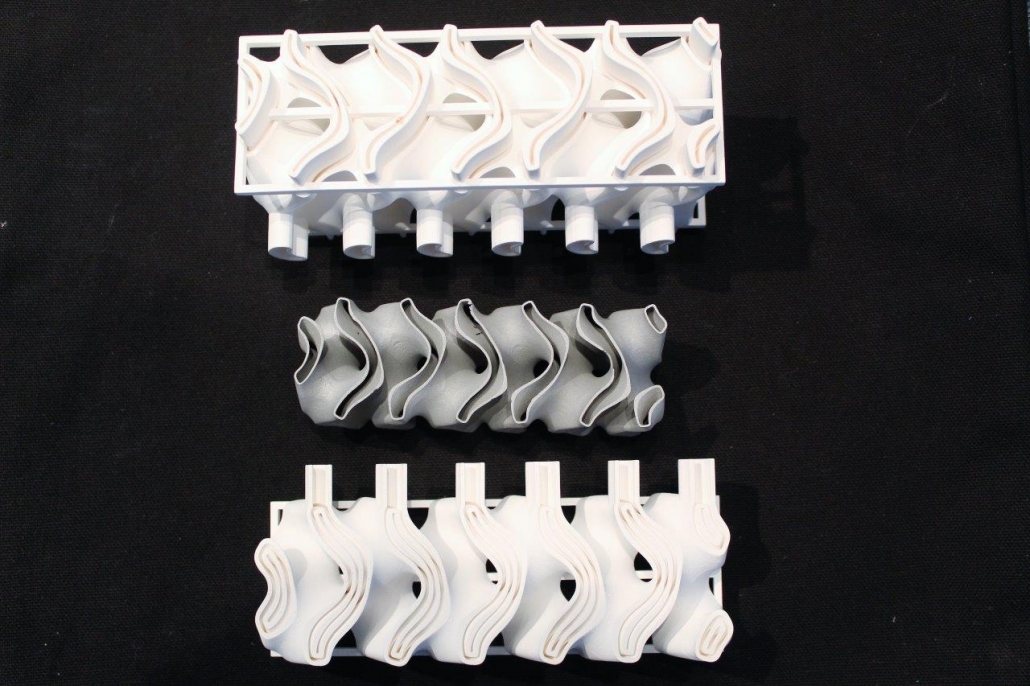

Printed investment casting shell (P.I.C.S.) technology is a new 3D printing process that is revolutionizing the investment casting industry. This process uses a 3D printer to create ceramic shells that are used to cast metal parts. The shells are printed directly from a digital model, which eliminates the need for traditional investment casting tooling. This makes it possible to produce complex, high-quality castings much faster and more cost-effectively than ever before.Printed investment casting shell technology is a game-changer for the investment casting industry. Advantages of using printed investment casting shell technology:

- Faster production times: The entire investment casting process can be completed in a matter of days, compared to weeks or even months with traditional methods.

- Lower costs: The cost of tooling is eliminated, and the printing process is much more efficient than traditional investment casting methods.

- Improved accuracy: The 3D printing process is very precise, which results in castings with excellent surface finish and dimensional accuracy.

- Greater design freedom: The ability to print complex geometries directly from a digital model gives designers more freedom to create innovative new products.

- Reduced waste: The 3D printing process is much more sustainable than traditional investment casting methods, which generate a significant amount of waste.

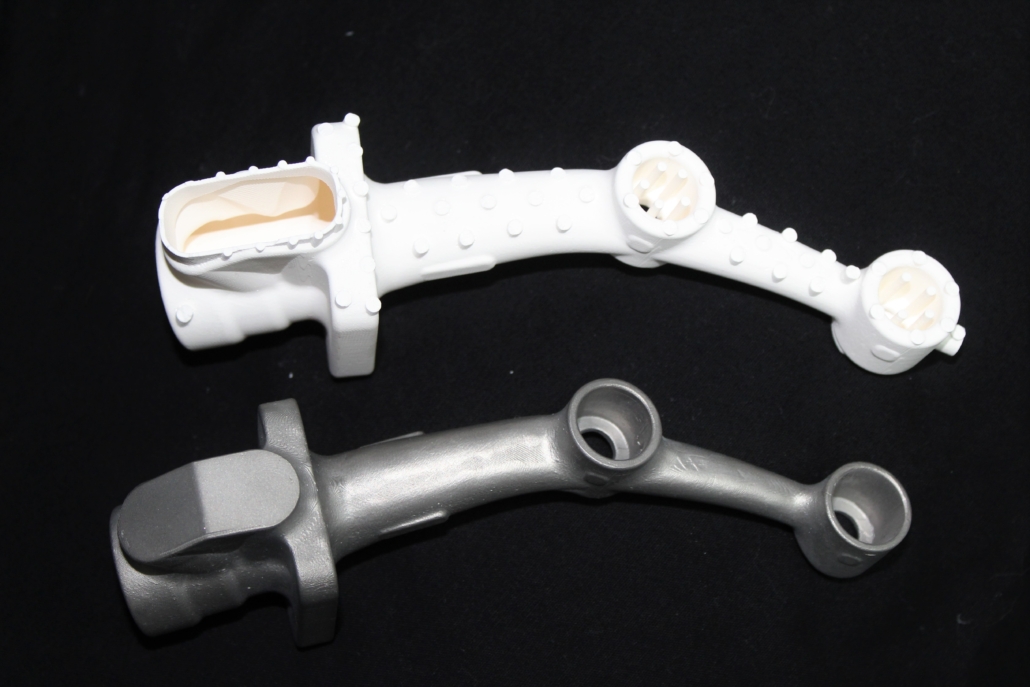

This duplex fuel nozzle has been investment cast using the P.I.C.S. (Printed Investment Casting Shell) process.