What is investment casting?

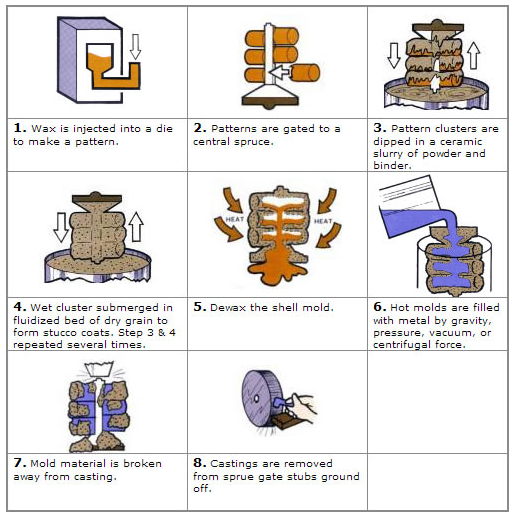

The term “investment” may bring dollar signs before the eyes of those who are not familiar with the process. Actually, it refers to the ceramic materials that are used to build a hollow shell into which the molten metal is poured to make the castings. The origin of the term investment comes from the solid mold process where a plaster type material is poured or “invested” into a container that holds a clustered tree of small plastic patterns that are identical to the casting being produced. After the plaster has set, the disposable patterns are burned out leaving a hollow cavity into which the metal is poured.

The same holds true for the investment or “lost wax” casting process. Wax is injected into an aluminum die to produce a pattern that is an exact replica of the part to be produced. For every casting, a wax pattern must be manufactured. The patterns are clustered around a coated sprue and repeatedly dipped into an agitated vat of ceramic and allowed to dry. After a shell thickness of approximately 3/16″ has been built; the molds are dewaxed by either flash firing at high heat (1400 F.) or autoclaving (pressure and steam). The hollow shells are then preheated to 800-2000 F. depending on the alloy to be poured and the molten metal cast immediately into the hot shell. After cooling, the ceramic is vibrated and blasted off the metal parts and discarded. The balance of the cleaning operations (cut off, grind, heat treat, straightening, blast) are straight forward and quite similar to the other casting processes.

-

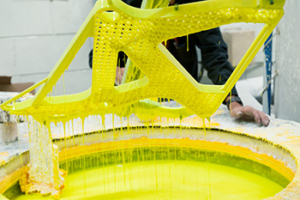

Shells in 8 Hours

We pioneered the use of G2 Technologies for shell building and are able to make shells in less than 8 hours.

-

Reverse Engineering

Our in-house blue light 3D scanners give us the capabilities to reverse engineer your parts to create a solid model file. We are able to scan parts starting at 0.250 inches to 10 feet in size.

-

Dimensional

We use a DCC/CMM (Hexagon) for dimensional validation and SPC data if required. The above mentioned blue light scanner can also be used to visually validate your part to a solid model file.

-

Internal Visual Inspection

We use a Borescope for inspection on all internal cavities. If required we would be able to provide you with pictures of the interior areas inspected.

-

Testing

Our in-house spectrometer is used to ensure your alloy meets the desired chemistry specification. We have hardness testers to check the hardness of alloys to spec.

- Rockwell Hardness Tester

- King Portable Brinell Hardness Tester

- Clark Handheld Hardness Tester

-

CAD

We use Mastercam 2020, GibbsCam 2016, Materialise Magic’s 25, and Spaceclaim 2020 software along with the ability to digest and/or modify virtually all solid model files.

-

Concurrent Engineering

When requested, we will send out one of our highly talented engineers to aid in your design for investment casting to optimize the processes capabilities and minimize your cost. This upfront engineering can save dramatically when all things are considered, such as weight and strength requirements and whether we can combine two or more details to eliminate assembly. We can help with your selection of the correct alloy and heat treat along with coating. These alone can help you get it right the first time. Couple these with our ability to supply an ABS model of your part for form-and-fit verification and you’ll understand the added value you receive when working with Magnesium Solutions.